Modern concrete infrastructure faces constant stress from traffic and the environment. Instead of repeatedly reactive repairs, a proactive approach uses advanced materials to fix damage early and guard against its recurrence. By combining fast-curing, high-strength products with innovative application techniques, we can extend a structure’s service life while minimizing downtime and structural strain.

Common Causes of Concrete Deterioration

Heavy Traffic & Mechanical Wear: Continuous vehicle loads and abrasion (especially on bridges and highways) lead to cracks, surface spalling, and potholes over time.

Freeze-Thaw Cycles & Deicing Salts: Water penetrating concrete expands when frozen, cracking the material. Road deicing chemicals accelerate this damage and can also attack the concrete chemically.

Rebar Corrosion (Chlorides & Carbonation): Ingress of chlorides (from marine exposure or salts) and carbonation of concrete lower the protection around steel reinforcement, causing it to rust. Expanding rust then cracks and delaminates the surrounding concrete.

Structural Movement & Thermal Stress: Settlement, seismic events, and temperature changes create internal stresses. These can result in shrinkage cracks, joint failures, or other compromises in the concrete.

Addressing these issues requires targeted strategies and specialized materials. Zrete’s Concrete Repair Solutions are grouped into key categories, each designed to tackle specific problems and restore the integrity of the concrete:

Crack Injection Resins

Fine cracks can significantly reduce a concrete structure’s durability by allowing water and aggressive agents inside. Our epoxy crack injection resins penetrate deeply into cracks to bond concrete back together and seal out moisture, preventing further expansion of the crack and corrosion of rebar. With varied viscosities and strengths, these two-component resins can treat everything from hairline fissures to wider voids in bridges, dams, tunnels, and foundations. They cure to form a high-strength, impermeable seal that restores structural continuity and stops leaks, even in damp conditions or moving cracks.

Structural Repair Mortars

Damaged concrete surfaces and sections (such as spalling concrete, chipped columns, or delaminated areas) are rebuilt using our high-performance repair mortars. These cement-based mortars are polymer-modified (using neoprene latex, acrylic emulsions, etc.) to achieve excellent bonding to old concrete, reduced shrinkage, and enhanced flexibility. Many include corrosion inhibitors or anti-corrosion properties to protect embedded steel reinforcement as the repair is made. Structural repair mortars restore the integrity and profile of the concrete element – whether patching a bridge deck corner, repairing an overhead beam, or fixing an eroded sidewalk – while ensuring the new material will not crack or debond under service conditions. They are thixotropic (non-sag) for easy application on vertical or overhead surfaces, and cure to high compressive strength for load-bearing performance.

Rapid-Setting and High-Strength Concretes

When repairs must be carried out under tight time windows (for example, on busy highways, airport runways, or live industrial facilities), rapid-setting concrete solutions are essential. Zrete offers fast-curing, high-early-strength concretes and mortars that achieve structural strength within hours, drastically reducing downtime. These materials allow traffic or service to resume quickly – in some cases, enabling half-width (half-lane) construction so that one side of a bridge or road remains open during repairs. Despite their quick set times, our rapid repair concretes are engineered for high ultimate strength and durability, with formulations that control shrinkage and even exhibit slight expansion to ensure a tight fit in repair cavities. This category includes polymer-enhanced concretes (like epoxy-based or polyurethane-based concretes) for flexible, chemical-resistant repairs, as well as specialty cementitious mixes for patching and resurfacing. They are ideal for emergency pavement repairs, expansion joint rebuilding, and cold-weather or winter works where normal concrete would cure too slowly.

Advanced Overlays and High-Performance Concrete

For extensive rehabilitation or strengthening projects, ultra-high performance concrete (UHPC) and advanced overlay systems provide exceptional results. These materials achieve very high compressive strength (100–150 MPa or more), exceptional bonding, and extremely low permeability. By applying a thin UHPC overlay or shotcrete layer to a deteriorated concrete surface (such as a bridge deck, parking structure, or tunnel lining), the structure gains a new protective wearing course that is far more durable and longer-lasting than conventional concrete. UHPC’s superior strength allows overlays to be thinner and lighter, adding minimal load while greatly extending service life. In addition, UHPC and high-performance mortars have excellent resistance to chloride penetration, freeze-thaw damage, and abrasion. This makes them especially suited for critical infrastructure in harsh environments – for example, bridge decks in cold climates or coastal piers exposed to saltwater. Our advanced concrete solutions can also be used for precast elements and structural infill where maximum performance is required in a compact form.

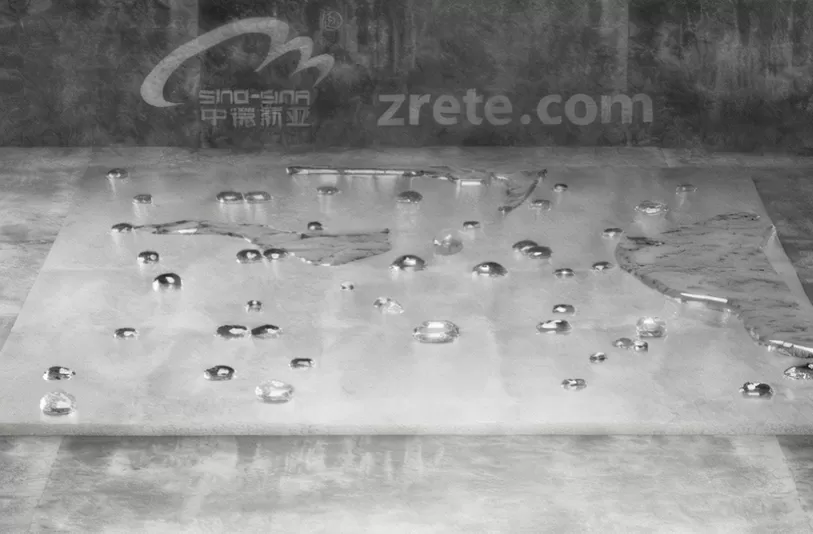

Protective Sealers and Coating Systems

Long-term concrete durability isn’t just about structural repair – it also requires protecting the repaired concrete from future aggression. Protective sealers and coatings are applied as a final step to seal pores, repel water and chemicals, and shield against weathering. Zrete offers penetrating sealers like silane-based treatments that soak into concrete surfaces and create an invisible hydrophobic barrier; this prevents water and chlorides from soaking in, thus combating rebar corrosion and freeze-thaw damage without altering the appearance of the concrete. In addition, interface bonding agents (applied as primers) ensure that repair materials securely bond to the old substrate and often contain corrosion inhibitors to protect reinforcing steel at the interface. Our protective coating systems are especially valuable in extreme environments – for example, on road surfaces subject to deicing salts, marine structures exposed to salt spray, or industrial floors exposed to chemicals. By sealing cracks and surfaces against moisture and carbonation, these products extend the life of both the original concrete and the new repairs.

Zrete’s Concrete Repair Solutions combine these technologies into a comprehensive toolkit for infrastructure owners. By actively repairing and protecting concrete structures – rather than simply reacting to failures – our solutions help significantly prolong service life and reduce life-cycle maintenance costs. From sealing hairline cracks in a parking garage to rebuilding and safeguarding a highway bridge deck, Zrete provides the materials and expertise to keep concrete infrastructure safe, strong, and resilient for decades to come.